- BARCODE PRODUCER ISM SERIAL

- BARCODE PRODUCER ISM DRIVER

- BARCODE PRODUCER ISM SOFTWARE

- BARCODE PRODUCER ISM BLUETOOTH

- BARCODE PRODUCER ISM MAC

Here are some of the commands: UART Communication Test: AT Read Firmware Version: AT+VER Read/Write Local Name: AT+NAME ġ600hops/sec, 1MHz channel space,79 Channels(BT 4. Connect to the modules and send the AT commands or test data transceiver. Plug the USB dev board into the computer USB port directly.

BARCODE PRODUCER ISM SERIAL

Download FeasyBlue App from Apply store or Google play store, or ask the serial port tools from customer suppporter.

BARCODE PRODUCER ISM DRIVER

Feasycom also provide serial port driver and the SDK of serial port tools.

BARCODE PRODUCER ISM BLUETOOTH

The easiest USB development board, customers can directly plug in the computer USB port to test the Bluetooth function, with FEASYCOM serial debugging tools, users can test AT command, data transceiver, and flow control will be convenient for customers to test Bluetooth function and performance without the motherboard being tuned. ◆Bluetooth stack profiles support: SPP, HID, MAP, and all BLE protocols. Design, customize, and send vector EPS barcodes graphics to your desktop, your printer, or direct to apps like.

BARCODE PRODUCER ISM MAC

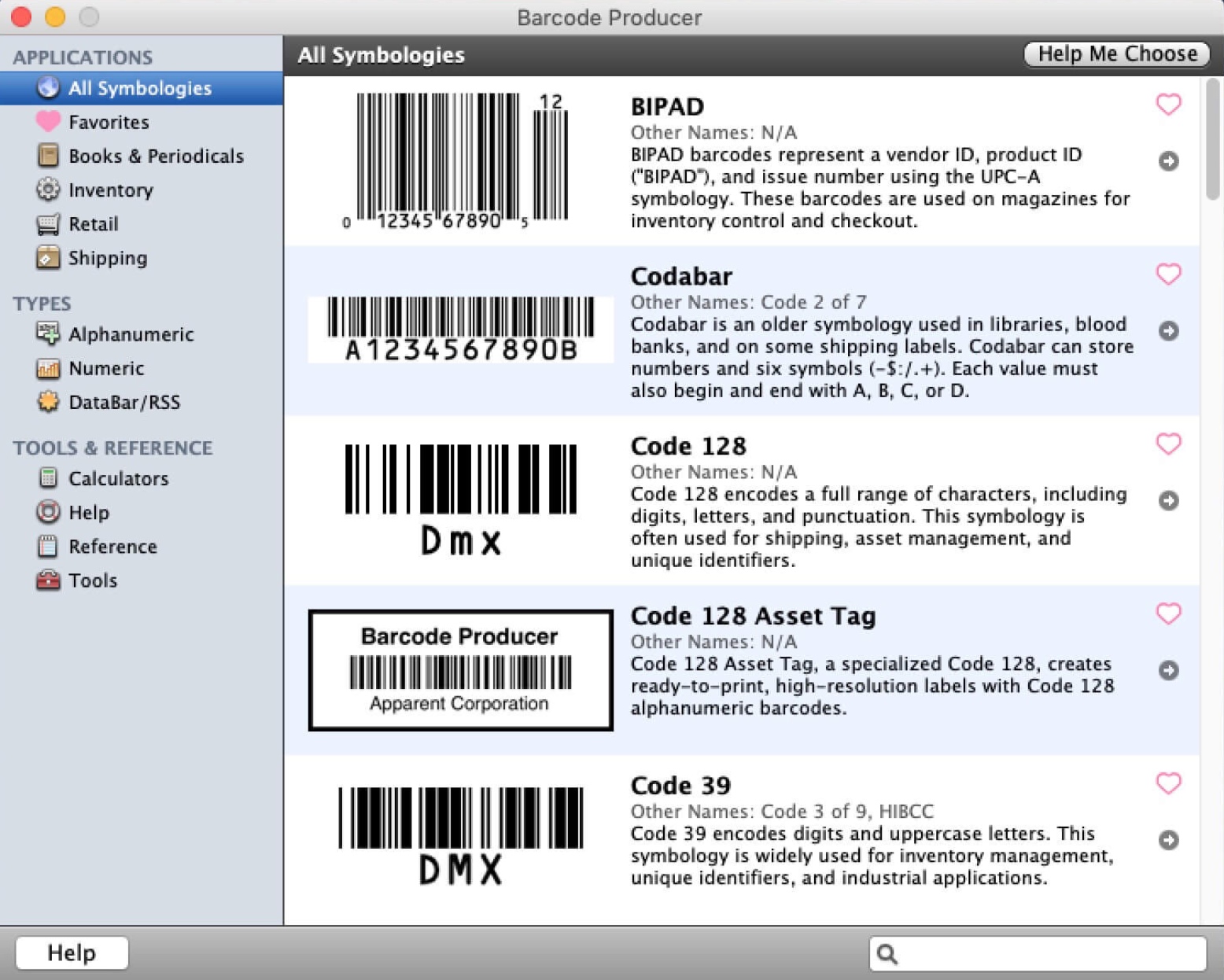

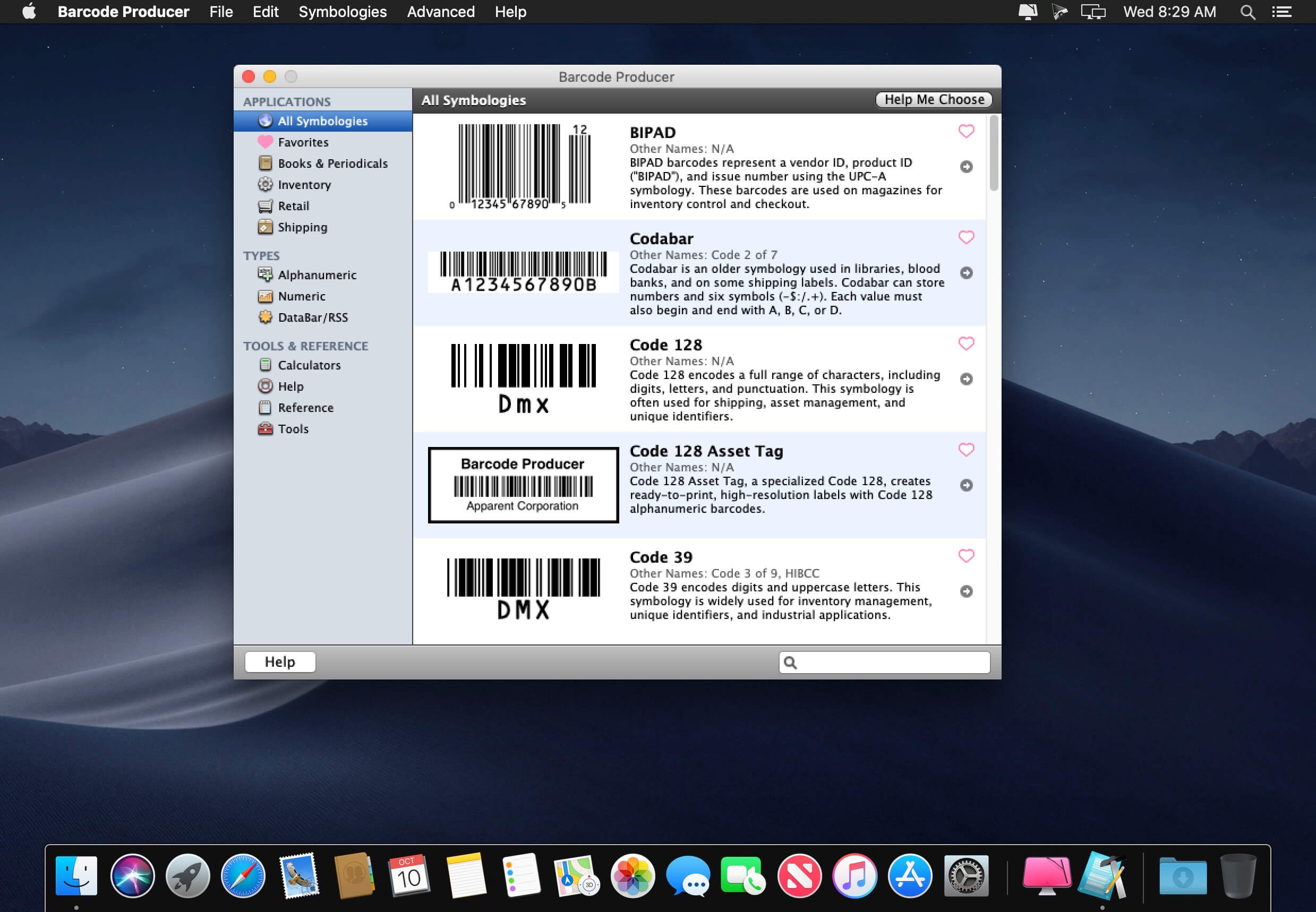

Barcode Producer generates perfect barcodes for retail, labels, books, packages, tags, and more on your Mac or PC, with clever features and tools for everything you need. Researchers estimated the monthly savings added up to 5,454 euros (6,059) for workforce, and 15,625 euros (17,357) for product loss and penalty.

BARCODE PRODUCER ISM SOFTWARE

◆UART, I2C,PCM / I2S data connection interfaces. The amazing barcode software for smart designers like you. The use of RFID by a Turkish denim manufacturer resulted in reduced labor cost and product loss, according to a 2017 paper published in The International Journal of Advanced Manufacturing Technology. This includes A-1 Packing Solutions, which filed a patent application earlier this month for a system that would use RFID tags on inventory to communicate with warehouse transportation equipment to help workers find misplaced inventory.Introduce: ◆Fully qualified Bluetooth 4.2/4.0/3.0/2.1/2.0/1.2/1.1 ◆Dimension: 13mm x 26.9mm x 2mm ◆Class 1.5 support(high output power) ◆The default UART Baud rate is 115.2Kbps and can support from 1200bps up to 921Kbps. More organizations are starting to think about how this technology can be used to deal with product losses. More recently, Nike has credited RFID for providing it with "the most complete view of our inventory that we have ever had," Nike CEO Mark Parker said this summer. Target cited the technology for improving its cost management when it came to payroll and inventory in 2016. Many large companies are already years into the use of RFID for inventory tracking. Throughout the manufacturing process, the RFID-embedded denim would communicate with eight RFID readers throughout the factory to provide real-time location information. The final cost comparison included the labor required to sew in the RFID tags and remove them before shipping. The factory needed 18 employees to handle barcode reading but only needed 10 for RFID scanning. The researchers also found RFID scanning required about half as many employees as barcode scanning. The lost and faulty rate prior to the use of RFID was 2% this was cut in half with RFID use. "Decreasing rate of lost items is an important parameter for denim production because product loss and related penalty cost factors have a high proportion on the total process cost value," the paper concluded. The savings resulting from reduced product loss will vary depending on any given organization's baseline for that particular issue. The report's benefit analysis estimated a product loss rate decrease of 50% to get an annual savings of 187,500 euros ($208,289). Researchers tested silicone, plastic and epoxy tags, concluding the epoxy ones were easiest to connect to the denim and could survive the manufacturing process.

Researchers estimated the monthly savings added up to 5,454 euros ($6,059) for workforce, and 15,625 euros ($17,357) for product loss and penalty costs.The use of RFID by a Turkish denim manufacturer resulted in reduced labor cost and product loss, according to a 2017 paper published in The International Journal of Advanced Manufacturing Technology.

0 kommentar(er)

0 kommentar(er)